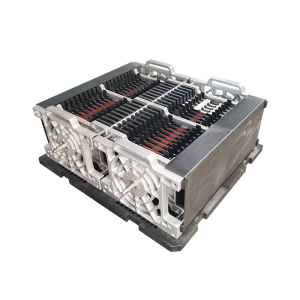

Pouch Battery Tray With Screen And Silicon Pad

Application

The tray is specially designed for storage and handling of pouch cells during the formation and part-volume processes of battery production.

Our pouch battery trays are specifically designed to meet the size requirements of pouch batteries, ensuring they fit securely and comfortably within the tray. This ensures that the cells remain safe and in place during the formation process, ensuring optimal performance of the final product.

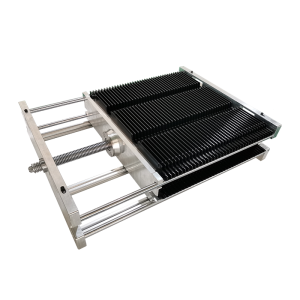

Made of high-quality materials, our pouch battery trays are durable enough to withstand the demands of continuous use and storage. The tray is also resistant to damage from heat and other environmental elements, further enhancing its reliability and value.

The unique design of our pouch battery tray ensures that it is easy to handle and transport. Its shape makes it ideal for use in automated production lines, allowing for efficient and streamlined operations.

We understand the importance of safety when dealing with battery storage and handling, which is why our pallets comply with all relevant safety standards. This ensures your staff can handle pouch batteries with confidence while minimizing the risk of accidents.

In addition to their practical benefits, our pouch battery trays also have an aesthetic design, making them a great addition to any production facility.

Our pouch battery trays are an essential part of an orderly, efficient and safe production process.

Feature

An outstanding feature of our pouch battery tray is its ability to compress batteries. Due to its unique design, it simplifies the device process and makes it easier for you to use and dispose of the battery. That means no more struggling with complicated devices or complicated programs - just pop the batteries in the tray, and you're ready to go!

Another great feature of our pouch battery tray is its potential for cost savings. With its cutting-edge technology, you'll be able to save on equipment costs as well as the cost of replacing batteries yourself. That's because our trays are designed to allow you to change battery models quickly and easily, saving you time and hassle in the process. This is especially useful for industries that require frequent battery changes, such as the transportation and logistics industry.

In today's fast-paced world, time is of the essence, which is why we designed our pouch battery trays to be fast and efficient. With its Rapid Battery Model Swap technology, you'll be able to swap batteries in record time, allowing you to focus on your work and get it done as quickly and easily as possible.

List of customer purchasing concerns

1.What are the differences of your products in the industry?

We can offer many kinds of trays ,including plastic trays,restrained trays and customize the relevant equipment which will be used in the battery production line

2.How long does your mold normally last? How to maintain daily?What is the capacity of each mold?

The mold is normally used for 6~8 years, and there is a special person responsible for daily maintenance. The production capacity of each mold is 300K~500KPCS

3. How long does it take for your company to make samples and open molds? 3. How long does your company's bulk delivery time take?

It will take 55~60 days for mold making and sample making, and 20~30 days for mass production after sample confirmation.

4. What is the total capacity of your company? How large is your company? What is the annual value of production?

It is 150K plastic pallets per year, 30K restrained pallets per year, we have 60 employees, more than 5,000 square meters of plant, On the year of 2022 ,annual output value is USD155 millions

5.What testing equipment does your company have?

Customizes the gauge according to the product,outside micrometers,inside micrometers and so on.

6. What is your company's quality process?

We will test the sample after opening the mold, and then repair the mold until the sample is confirmed. Large goods are produced in small batches first, and then in large quantities after stability.

Our Factory

Our Company

Lingying Technology were founded in 2017.Expand to be two factories in 2021,In 2022,was nominated as a high-tech enterprise by the government, basic on more than 20 invention patents.More than 100 production equipments,factory area more than 5000 square meters."To establish a career with precision and win with quality" is our eternal pursuit.

Certificates

Delivery