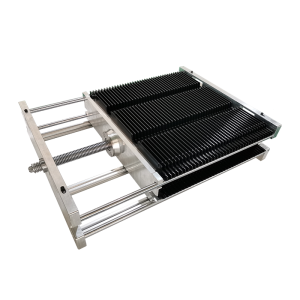

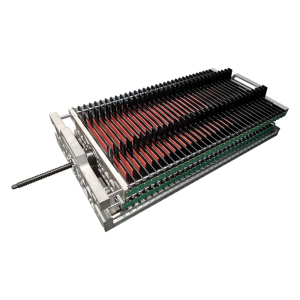

Prismatic Cell Pressurized Tray For Export

Product Advantages

1.The pallet has high security and is designed to minimize the risk of battery damage and accidents during transport.

2.Our restraint trays attach securely to the battery, ensuring minimal movement during transport and reducing the chance of damage from drops or bumps. This feature makes it a reliable solution for shipping batteries of all types, sizes and shapes. The trays are made of high strength plastic and steel, which combine to provide the best solution for stability and safety.

3.Our restraint pallets are designed to facilitate efficient storage and transport. Pallets are stackable on top of each other, which means that pallets can be secured together during storage and transport. This makes it possible to store and transport more batteries in less space, saving costs during shipping.

4.The materials used in our restraint trays are of the highest quality, ensuring durability and resistance to wear and tear. Pallets can withstand heavy loads, making them the ideal solution for battery storage and transport both at home and abroad.

5.Our restraint trays come in a variety of sizes to accommodate different battery sizes. We have a team of professionals dedicated to providing our customers with personalized assistance and assistance in choosing the right size and type of pallet for their needs.

Product Feature

During battery production, it is important to ensure that batteries are handled with care to prevent damage and ensure maximum efficiency. Using plastic battery trays can make this process easier and more efficient, avoiding manual handling and reducing the risk of breakage.

The Restrained Tray is designed to keep batteries safe and in place during storage and transport. Its unique design ensures batteries are neatly aligned and stacked for easy management and handling. By using Restrained Tray, manufacturers can speed up the production process without sacrificing quality, while dealers can provide customers with well-organized and displayed products.

Proper management and display of batteries is essential for battery dealers. The Restrained Tray enables dealers to efficiently organize their inventory, making it easy to find specific batteries. Not only does this save time, but it also ensures proper handling of the battery, thus preserving its quality and performance.

With the Restrained Tray, both battery manufacturers and distributors can benefit greatly. Not only does it improve battery handling and storage, but it also helps minimize damage and reduce losses, making battery production and sales more cost-effective. Also, the use of plastic material in the tray design makes it both durable and environmentally friendly.

Our Factory

Our Company

Lingying Technology were founded in 2017.Expand to be two factories in 2021,In 2022,was nominated as a high-tech enterprise by the government, basic on more than 20 invention patents.More than 100 production equipments,factory area more than 5000 square meters."To establish a career with precision and win with quality" is our eternal pursuit.

Certificates

Delivery

List of customer purchasing concerns

1.What are the differences of your products in the industry?

We can offer many kinds of trays ,including plastic trays,restrained trays and customize the relevant equipment which will be used in the battery production line

2.How long does your mold normally last? How to maintain daily? What is the capacity of each mold?

The mold is normally used for 6~8 years, and there is a special person responsible for daily maintenance. The production capacity of each mold is 300K~500KPCS

3. How long does it take for your company to make samples and open molds? 3. How long does your company's bulk delivery time take?

It will take 55~60 days for mold making and sample making, and 20~30 days for mass production after sample confirmation.

4. What is the total capacity of your company? How large is your company? What is the annual value of production?

It is 150K plastic pallets per year, 30K restrained pallets per year, we have 60 employees, more than 5,000 square meters of plant, On the year of 2022 ,annual output value is USD155 millions

5.What testing equipment does your company have?

Customizes the gauge according to the product,outside micrometers,inside micrometers and so on.

6. What is your company's quality process?

We will test the sample after opening the mold, and then repair the mold until the sample is confirmed. Large goods are produced in small batches first, and then in large quantities after stability.